- ブランド

- ブランド

- 採掘および建設シミュレーター

- トレーニングシステム

- ポートシミュレーター

- トレーニングシステム

- 工業用シミュレーター

- トレーニングシステム

- Gallery

- トレーニングシステム

- ハードウェアコンポーネント

- ハードウェア

- シミュレーターステーションのオプション

- ハードウェア

- トレーニング シミュレータを使用する理由?

- ハードウェア

- Technical information

- ソフトウェア

- Our Solutions

- ソフトウェア

- Instructor Information

- ソフトウェア

- コラボレーションモード

- ソフトウェア

- Services

- 当社のサービス

- Ship-to-Shore Crane Simulator

- シミュレーター

- Bulldozer Simulator

- シミュレーター

- Mobile Harbour Crane Simulator

- シミュレーター

- Mining Truck Simulator

- シミュレーター

- Wheel Loader Simulator

- シミュレーター

- Underground LHD Loader Simulator

- シミュレーター

- Forklift Simulator

- シミュレーター

- High Capacity Forklift Simulator

- シミュレーター

- 360 Excavator Simulator

- シミュレーター

- Mobile Crane Simulator

- シミュレーター

- Rail Mounted Gantry Crane Simulator

- シミュレーター

- Tower Crane Simulator

- シミュレーター

- Rubber-Tyred Gantry Crane Simulator

- シミュレーター

- Telehandler Simulator

- シミュレーター

- Grader Simulator

- シミュレーター

- Reach-Stacker Simulator

- シミュレーター

- Backhoe Simulator

- シミュレーター

- Ro-Ro Simulator

- シミュレーター

- Straddle Carrier Simulator

- シミュレーター

- WheelDozer Simulator

- シミュレーター

- アーティキュレート鉱山トラックシミュレーター

- シミュレーター

- Electric Shovel Simulator

- シミュレーター

- Empty Container Handler Simulator

- シミュレーター

- Drilling Jumbo Simulator

- シミュレーター

- Bridge Crane Simulator

- シミュレーター

- Farming Tractor Simulator

- シミュレーター

- Harvester Simulator

- シミュレーター

- 船舶用ペデスタルクレーンシミュレーター

- シミュレーター

- 自走式屈伸型高所作業車シミュレータ

- シミュレーター

- グループビジョン

- 会社情報

- 学習方法論

- 会社情報

- Contact

- お問い合わせ

ソフトウェア

LSyM が開発した各機器には、機械とその環境の挙動を正確かつ現実的に計算する特定の数学モデルが備わっています。シミュレーションに関して言えば、主な目的は学習であるため、ビジュアル モデルがグラフィック的に魅力的であるだけでは十分ではありません。 機械、物体、環境の動作が実際の動作と似ていることが重要です。

マシンの動作は、GPU ベースの物理ライブラリである NVidia PhysX を使用して計算され、凸メッシュ ベースの衝突オブジェクトの使用が可能になります。 これにより、非常に正確な衝突検出が保証され、他のオブジェクトと衝突する滑車に基づいた現実的なケーブル モデルの実装が保証されます。

グラフィック システムは、1 ~ 12 のビデオ チャネルの高品質視覚化システムを使用してユーザーに表示される 3D グラフィックによってシーンの視覚表現を生成します。

シミュレーターにはシミュレーション画面やタッチパネルに表示されるHUD (ヘッドアップディスプレイ) が付いています。 これには、機械の状態インジケーター、機械の位置インジケーター、環境のさまざまなビューなど、実際の機械によってオペレーターに提供されるすべての追加情報が含まれます。

さらに詳しい情報が必要な場合は、当社のチームがいつでも喜んでサポートいたします。

私たちの解決策

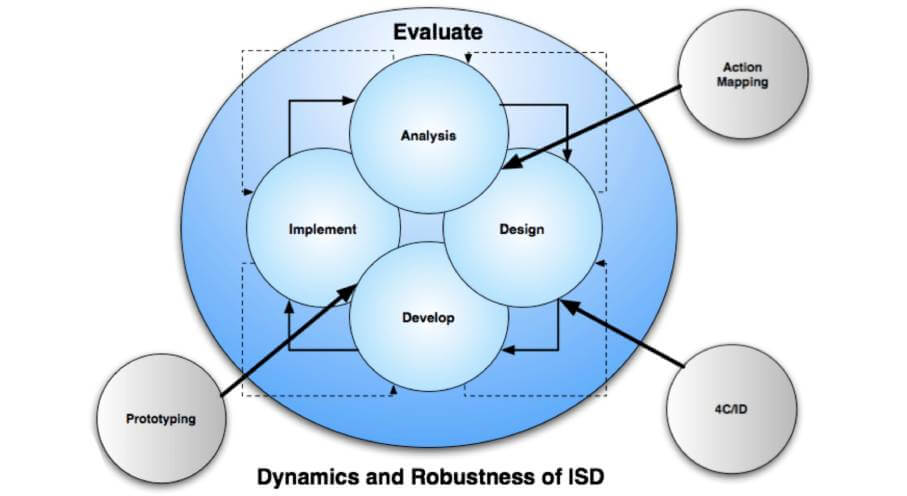

命令システム設計(ISD)

ほぼ 30 年にわたって得た経験の結果、LSyM は幅広いシミュレーション マシンを設計するだけでなく、独自の命令システム デザイン (ISD) も提供します。

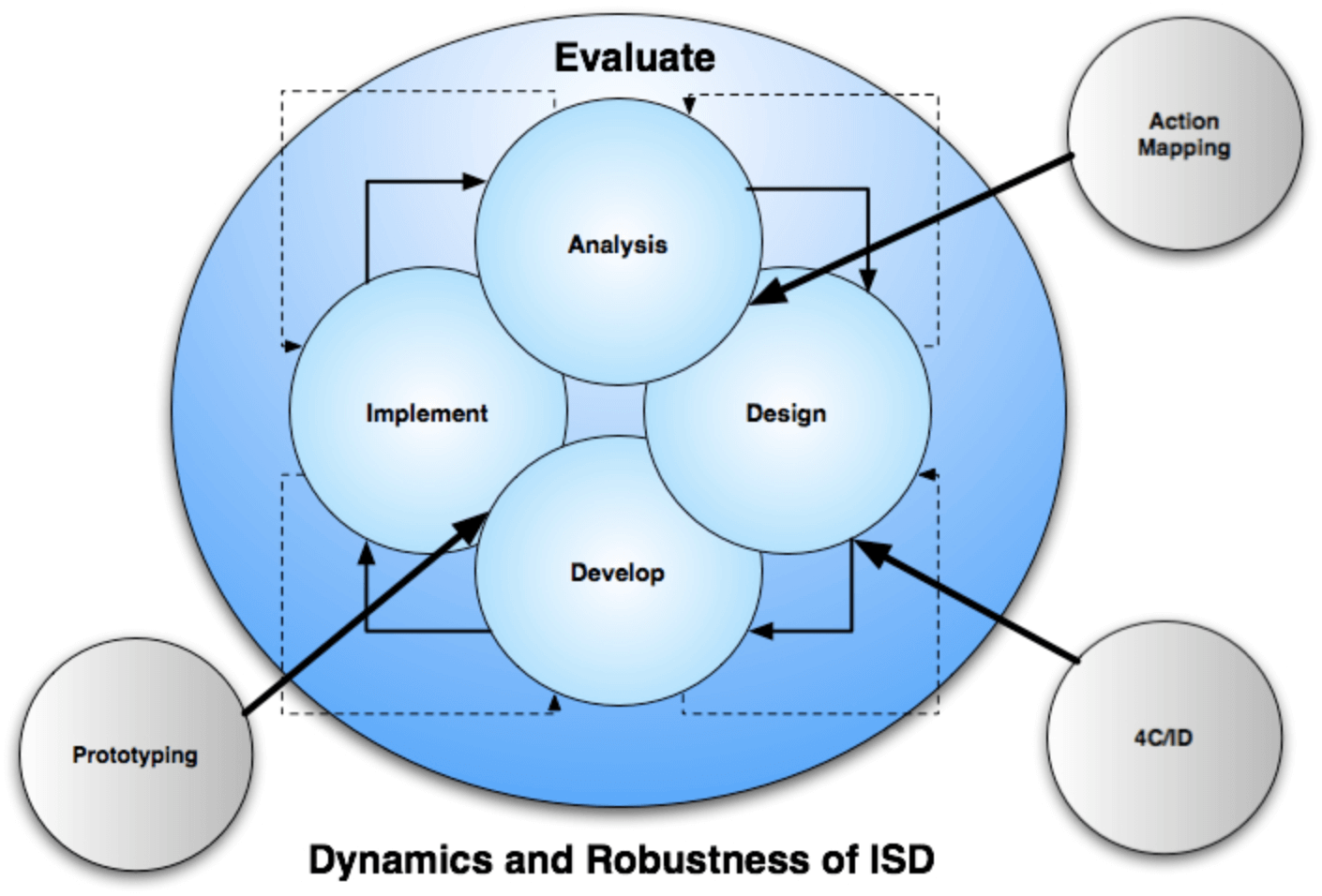

THEORETICAL MODULE

Theoretical Course is a complementary tool which was designed to support instructors during the course. The number and content of these modules vary depending on a machine. Therefore, some machines have a very extensive theoretical information and some does not include this part.

PRACTICAL EXERCIES

A set of didactic materials and tools based on the experience of advanced users and traditional training procedures.

EVALUATION SYSTEM

A set of evaluation tools help the instructor to follow the progress of each of the students with rigor and objectivity.

INSTRUCTIONAL SYSTEMS DESIGN (ISD)

As a result of the experience gained over almost three decades, LSyM not only designs a wide range of simulating machines, but also offers a unique Instructional Systems Design.

Instructional Systems Design is a complex System that ensures that all learning material was developed specifically for the education purposes which allows defining the end goals and objectives of instruction, designing and planning assessment tasks, and designing teaching and learning activities to ensure the quality of instruction. This Systems Consists of Theoretical Module (in the majority of the machines), Practical Exercises and Evaluation System.

THEORETICAL MODULE

Theoretical Course is a complementary tool which was designed to support instructors during the course. The number and content of these modules vary depending on a machine. Therefore, some machines have a very extensive theoretical information and some does not include this part. All provided information however, is self-explaining and easy to follow hence can be read by alumni independently.

This module describes topics such as:

- Introduction to the machine.

- Risk prevention.

- Operation security.

- Knowledge of the components.

- Basic maintenance.

- Protocols during the usage.

- Procedures.

- Malfunctioning of the machines.

- Possible problems during the usage.

PRACTICAL EXERCIES

A set of didactic materials and tools based on the experience of advanced users and traditional training procedures.

It sequences the skills to be acquired following a pre-established correct order, which is necessary in achieving the best results. Systematic practices allow users to get the most out of the equipment, acquire necessary skills and minimize the training time. In addition, the instructor has flexibility in modification of courses depending on the learning objectives, as experienced users who want to enhance their practical skills might need a different approach from those learning the skills from the beginning.

Example of Modules and ExercisesRISK MANAGEMENT EXERCISES

The main goal of a training simulator is that users learn how to use different machines without the need of using a real one, avoiding risks. Hence, it is crucial for a simulator to mimic possible situations identical to those, that can occur in a real life.

Our software allows the instructor to modify conditions of the simulation and inject various faults into the machine during the execution of the exercise. The trainee must react appropriately, identifying the cause of the fault and perform an appropriate corrective action. Such exercises are very important in preparation for the unexpected situations in the real life.

REQUEST INFORMATIONCHANGES IN CONDITIONS

TIME OF DAY

Time of the day might affect alumni’s visibility and as result endanger alumni and his/hers surrounding. Illumination can be modified from full light to night time.

WEATHER CONDITIONS

Weather changes might have a significant effect on machinery operation. In addition to fog, rain and snow, instructor can also modify wind speed and wind direction.

INJECTABLE FAULTS

A part from achieving exercise goal, it is fundamental to monitor the machinery parameters as disregarding those, can lead to unavoidable consequences.

| EVENTS | CONSEQUENCES |

|---|---|

| Reversing beeper failure | Reversing buzzer does not sound |

| Low hydraulic oil level | Engine does not start |

| Low brake oil level | Engine stops |

| Transmission oil pressure too low | Brake release failure |

| Insufficient brake pressure in brake | Blade control does not work |

| Steering does not work | Cannot select gears |

| Pressure accumulator | Partial or total loss of service brakes |

| Engine oil pressure too low | Fire |

| Engine temperature too high | |

| Brake valve failure |

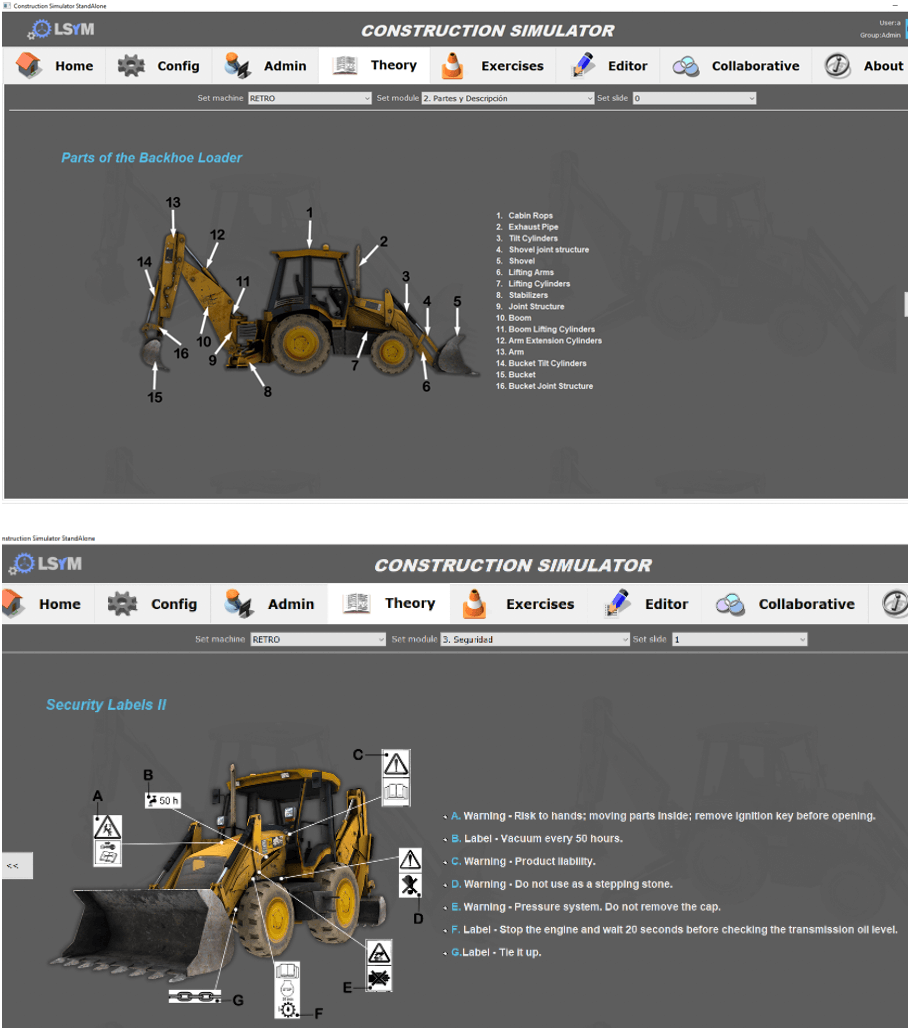

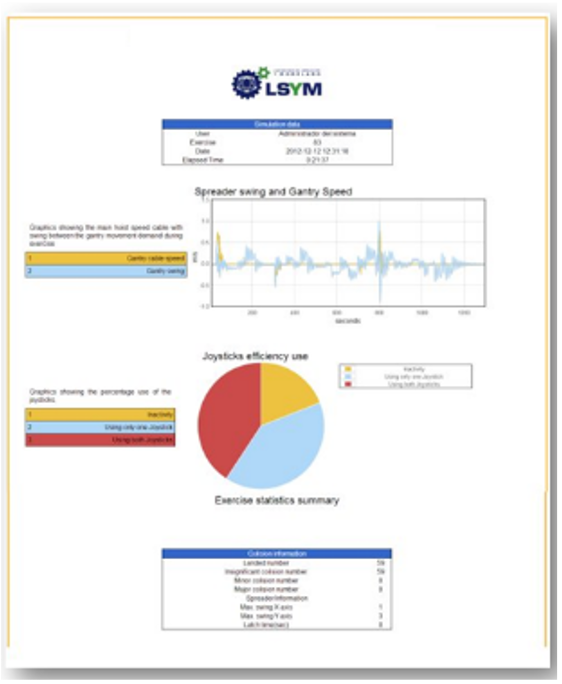

EVALUATION SYSTEM

A set of evaluation tools help the instructor to follow the progress of each of the students with rigor and objectivity. The system automatically generates a series of evaluation reports, which include relevant information on a wide variety of parameters of the exercises performed, as well as simulation data. The reports are generated for each of the exercises performed, as well as for the entire training process. This makes it possible to objectively quantify the level of expertise a user has achieved with the simulator. In this way, the instructor can gain justifiable confidence that a trainee has acquired sufficient skills to be able to use the real machine.

Evaluation and formation program features:

- Guided exercises with visual instructions on screen.

- Course manual with accurate description of the exercises and of the different skills to be acquired through every one.

- Database system to store all the information of each trainee and of advanced users.

- Record system to monitor the evolution of every user along the training program. Individual performance reports and statistical comparison with historical data.

- Exercise and overall reports, summaries, etc. with graphical plots and general information for each trainee.

- Possibility of introducing new parameters and data in the reports upon demand.

- Full control of the different tools from the instructor's console.

- Video recording of an exercise.

- Pause in the simulation that can be invoked from the instructor's console to give indications to the trainee at any moment during the simulation.

Reports at the instructor's console show:

- Date, time and duration information per exercise.

- Overall course information with finished exercises, average performance of the trainee, evolution along time, skills acquired, etc.

- Velocity log, and graphical plots of velocities. Maximum velocities record.

- Collision log, with track of collision velocities and of strong collisions.

- Graphical representation of trajectories of spreader, hook, vehicle, etc.

- Acceleration log, with record of dangerous accelerations, overload of the machinery, etc. and graphical plots.

- Record of dangerous or prohibited manoeuvres during the simulation.

- Statistical analysis of data to better plan future training programs.

These data allow instructor not only to evaluate individual student, but also to use it as a tool for statistical purposes such as analysing the data across different classes in the course of the year(s). This information later can be used by HR in modification of training program.

Risk Management Course

In addition, we have created a short risk management course in which instructors can learn quick and effective methods on developing risk management skills. We guide instructors by giving them the order of the exercises as well as demonstrate best ways of injecting scenarios, which are proofed to be the best way of achieving desired results. Contact us to find out more.