- ブランド

- ブランド

- 採掘および建設シミュレーター

- トレーニングシステム

- ポートシミュレーター

- トレーニングシステム

- 工業用シミュレーター

- トレーニングシステム

- Gallery

- トレーニングシステム

- ハードウェアコンポーネント

- ハードウェア

- シミュレーターステーションのオプション

- ハードウェア

- トレーニング シミュレータを使用する理由?

- ハードウェア

- Technical information

- ソフトウェア

- Our Solutions

- ソフトウェア

- Instructor Information

- ソフトウェア

- コラボレーションモード

- ソフトウェア

- Services

- 当社のサービス

- Ship-to-Shore Crane Simulator

- シミュレーター

- Bulldozer Simulator

- シミュレーター

- Mobile Harbour Crane Simulator

- シミュレーター

- Mining Truck Simulator

- シミュレーター

- Wheel Loader Simulator

- シミュレーター

- Underground LHD Loader Simulator

- シミュレーター

- Forklift Simulator

- シミュレーター

- High Capacity Forklift Simulator

- シミュレーター

- 360 Excavator Simulator

- シミュレーター

- Mobile Crane Simulator

- シミュレーター

- Rail Mounted Gantry Crane Simulator

- シミュレーター

- Tower Crane Simulator

- シミュレーター

- Rubber-Tyred Gantry Crane Simulator

- シミュレーター

- Telehandler Simulator

- シミュレーター

- Grader Simulator

- シミュレーター

- Reach-Stacker Simulator

- シミュレーター

- Backhoe Simulator

- シミュレーター

- Ro-Ro Simulator

- シミュレーター

- Straddle Carrier Simulator

- シミュレーター

- WheelDozer Simulator

- シミュレーター

- アーティキュレート鉱山トラックシミュレーター

- シミュレーター

- Electric Shovel Simulator

- シミュレーター

- Empty Container Handler Simulator

- シミュレーター

- Drilling Jumbo Simulator

- シミュレーター

- Bridge Crane Simulator

- シミュレーター

- Farming Tractor Simulator

- シミュレーター

- Harvester Simulator

- シミュレーター

- 船舶用ペデスタルクレーンシミュレーター

- シミュレーター

- 自走式屈伸型高所作業車シミュレータ

- シミュレーター

- グループビジョン

- 会社情報

- 学習方法論

- 会社情報

- Contact

- お問い合わせ

会社情報

LSYM is not just a company, our team is a group of academical investigators who have dedicated their life to the research in virtual reality, mathematical modelling, motion platforms and computer architecture. University PhDs and Professors, in areas of Computer Engineering, Mathematics and Physics have joined together for a common goal of creating the ultimate machinery simulator.

Their teaching experience and expertise allowed us to build a powerful tool that makes learning and teaching much easier, enjoyable and efficient.

Based at the Robotics Institute in the University of Valencia (IRTIC), we are in the heart of innovation. Our main line of interest is the development and integration of training systems for the operators, based on real-time simulation. This fact, allows us to be experts in machinery simulators and to manufacture a truly state-of-the-art product.

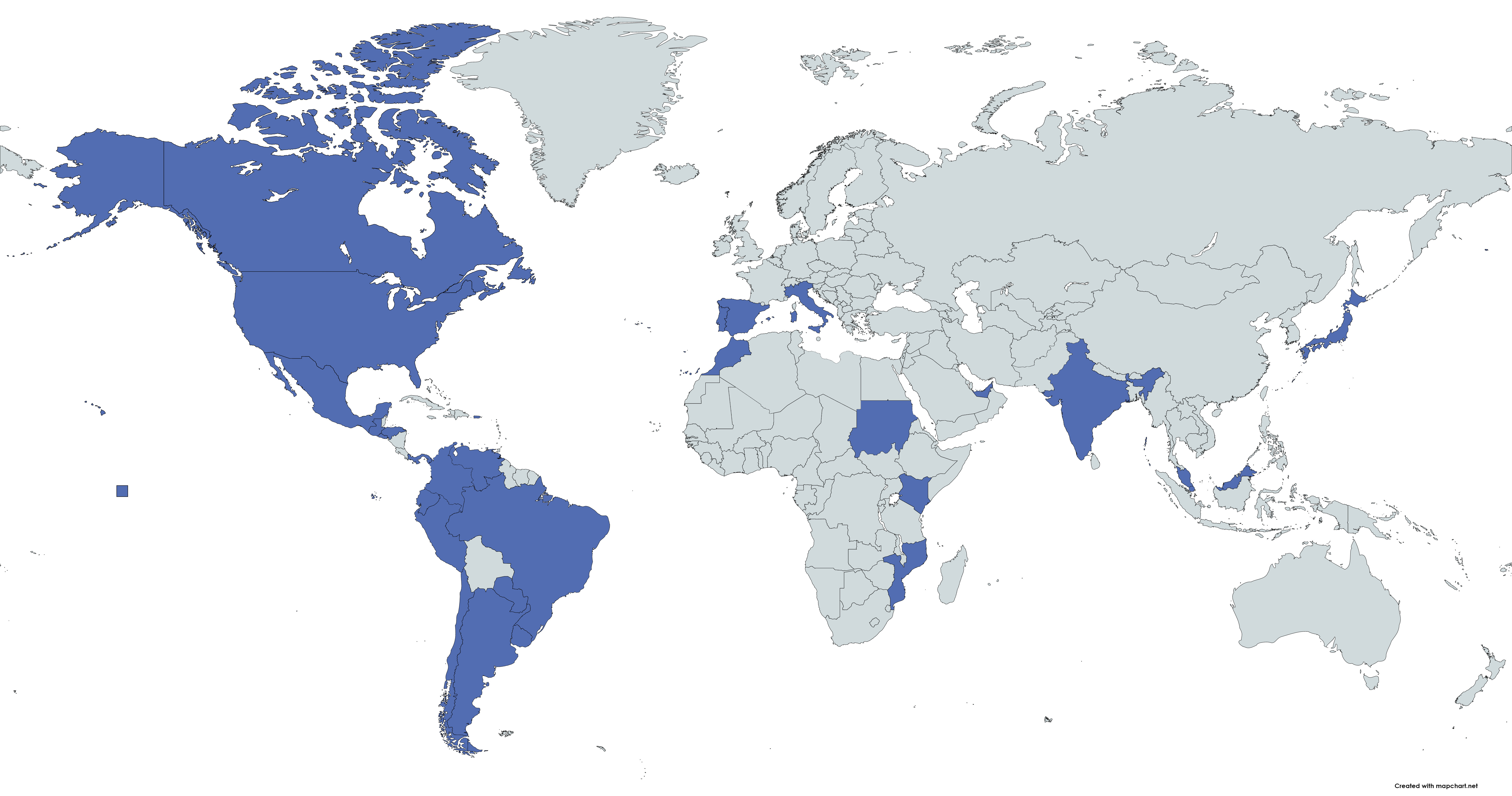

25+

Different Machines1000+

Simulators Installations50+

CountriesWHERE WE STAND

LSyM designs simulators since 1996.

We work with Software developed in house and IT infrastructure capable of providing international services.

Our unique Learning System guarantees quick and effective learning.

We are highly focused on sustainability in products and relationships with our customers and partners.

IF YOU NEED MORE INFORMATION, OUR TEAM IS ALWAYS HAPPY TO ASSIST

We dedicated nearly three decades to the research in different industries and have developed a state-of-the-art learning methodology to educate first class professionals using the latest advancements in information technology. This methodology is based on three basic principles which ensure the effective learning.

Understand

At LSYM we give a great importance to the quality of the entire learning cycle and make sure that each apprentice acquires the necessary skills and competencies in order to be the best at their profession.

Practice

Acquiring proficiency takes time and a lot of practice.

Evaluate

To make sure you provide fair and professional evaluations, it is crucial to guarantee that various factors have been considered.

Understand

At LSYM we give a great importance to the quality of the entire learning cycle and make sure that each apprentice acquires the necessary skills and competencies in order to be the best at their profession. Operating heavy machinery can be extremely dangerous if done by unprepared operators.

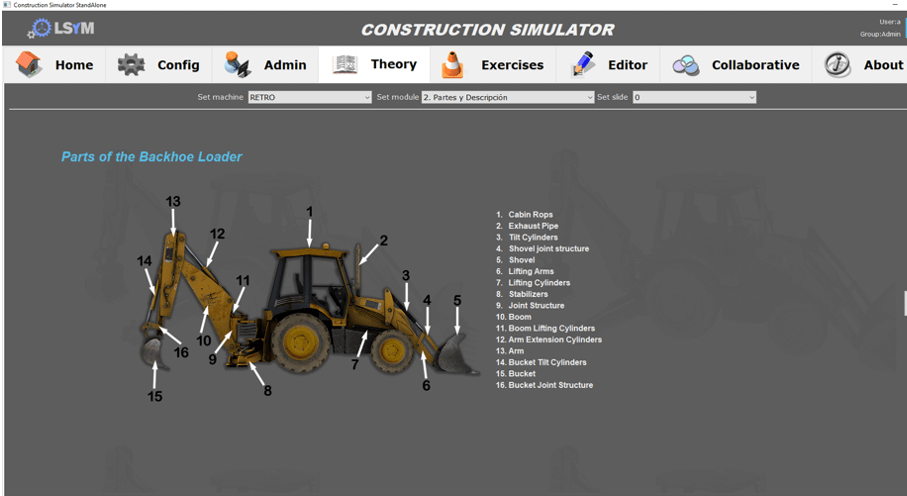

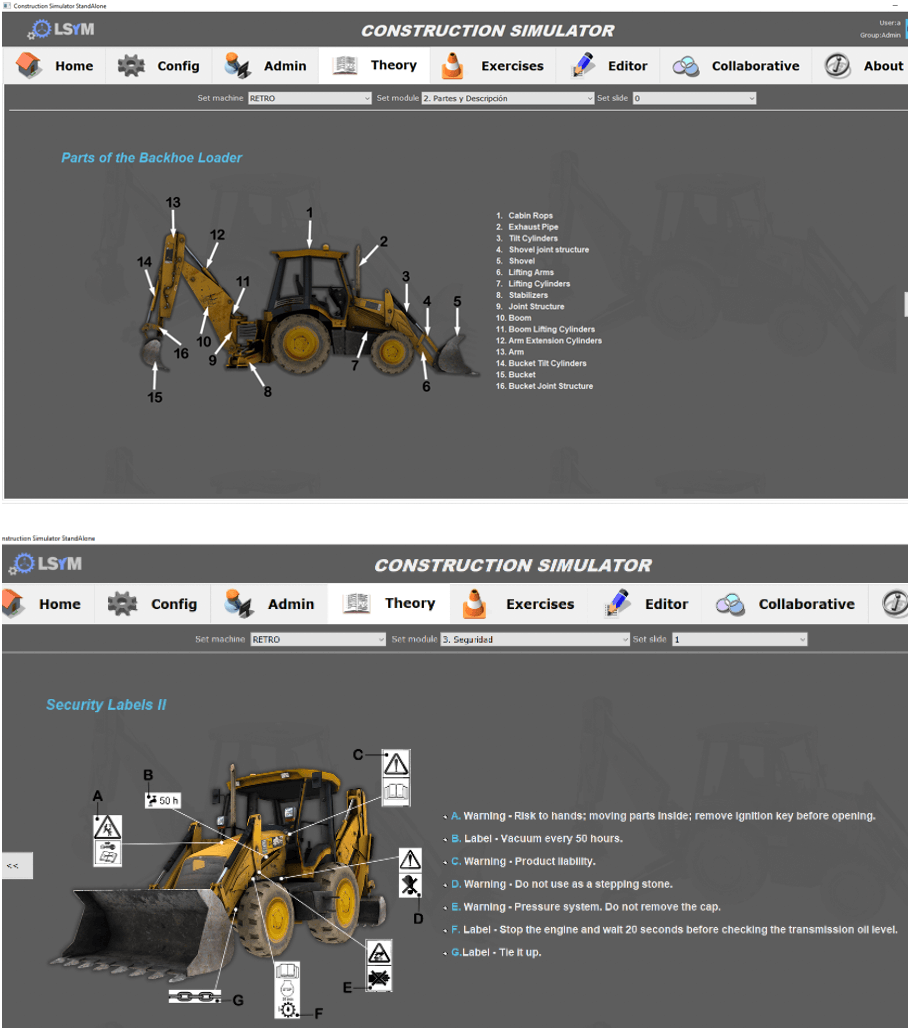

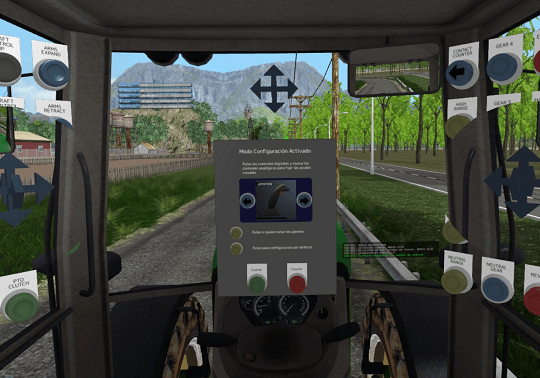

For this purpose, each simulator incorporates a Theoretical Module with which the student will acquire notions related to the knowledge of the machine, its operation and maintenance, the reaction to sudden breakdowns and, especially, everything related to risk prevention and safety. This Module can be read independently by students as well as used by instructors when preparing for a lecture.

Practice

Acquiring proficiency takes time and a lot of practice. It is a scientifically proven fact that practical knowledge is essential when learning a new skill and that repetition of a task leads to a greater learning effect. However, in order to gain a profound knowledge requires a set of right practical exercises and a complex learning approach.

One of the principal advantages of simulators is the flexibility in practicing for the alumni. One is not dependent on machine availability, weather conditions, financial expenses associated with operating or maintenance of the machine.

Evaluate

To make sure you provide fair and professional evaluations, it is crucial to guarantee that various factors have been considered. An assessment can be viewed successful, when:

- A fair and standardised metric system is applied.

- Impartial and skilled expert performs evaluation.

- Availability of a traceable record.

Our Evaluation method ensures that all these factors are fulfilled up to the highest standards.

The exercises of each virtual class can also be parameterized, establishing minimum scores, penalties, maximum number of repetitions, maximum times, if the exercise is mandatory to advance in the course, etc. Definition of such parameters ensures that equal is applied to all students as everyone’s performance is measured based on the same criteria.

Clients that already confide in us