- Home

- Home

- Mining and construction simulators

- Training Systems

- Port simulators

- Training Systems

- Industrial simulators

- Training Systems

- Gallery

- Training Systems

- Hardware Components

- Hardware

- Simulator Models

- Hardware

- Why Simulators?

- Hardware

- Technical information

- Software

- Our Solutions

- Software

- Instructor Information

- Software

- Collaborative Mode

- Software

- Services

- Services

- Ship-to-Shore Crane Simulator

- Bulldozer Simulator

- Mobile Harbour Crane Simulator

- Mining Truck Simulator

- Wheel Loader Simulator

- Underground LHD Loader Simulator

- Forklift Simulator

- High Capacity Forklift Simulator

- 360 Excavator Simulator

- Mobile Crane Simulator

- Rail Mounted Gantry Crane Simulator

- Tower Crane Simulator

- Rubber-Tyred Gantry Crane Simulator

- Telehandler Simulator

- Grader Simulator

- Reach-Stacker Simulator

- Backhoe Simulator

- Ro-Ro Simulator

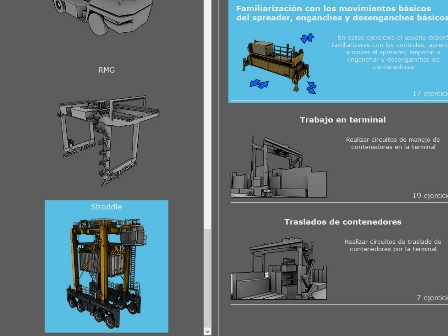

- Straddle Carrier Simulator

- WheelDozer Simulator

- Articulated Mining Truck Simulator

- Electric Shovel Simulator

- Empty Container Handler Simulator

- Drilling Jumbo Simulator

- Bridge Crane Simulator

- Farming Tractor Simulator

- Harvester Simulator

- Ship Pedestal Crane Simulator

- Mobile Elevating Work Platform (MEWP) Simulator

- About us

- About us

- Our Learning Methodology

- About us

- Contact

- Contact

A Straddle Carrier is a special mobile equipment for transporting ISO containers.It is used to manipulate containers inside the container terminals of ports, loading, unloading and stacking containers.

The vehicle consists of a structure in the form of a gantry and a lifting system (spreader) that can be moved in vertical direction with the help of a winch and serves to hoist the container.

During the displacement of the straddle carrier, the container is housed in the hollow of the structure. You can lift up to 60 tons, which is equivalent to two full-load containers. In addition, a straddle carrier can stack containers up to four heights.

The structure is equipped with a drive train with eight wheels, thanks to which you can move around the container terminal or the cargo terminal.They reach a maximum speed of 30 km / h when moving loaded containers. The gantry trucks do not circulate by road.

The driver's cab is located at the top of the structure so that the forward and backward visibility is maximum.

Operative

The straddle carrier approaches by the top of a container that is on the ground or in a trailer, the spreader is attached to the four corners of the container thanks to a hydraulic mechanism and that is when it is lifted and transported.

Why use the Straddle Carrier simulator developed by LSyM?

By using our simulator in addition to obtaining the necessary preparation to be able to undertake the operation correctly, you can avoid, among others, the following risk situations:

- Collisions against containers and other machines present in the terminal

- Accidents and entrapments

- Risks when loading on trailers

- Fires

- Thermal or/and electrical contact failures

Equipment

- Real operations console.

- Cabin implemented on a platform of 2 to 6 degrees of freedom.

- Real controls.

- Realistic machine sounds and surroundings.

- Console of the instructor with total control of the simulation.

- Projection system from 2 to 5 high resolution screens.

Display System

- Realistic 3D graphics.

- Implementation of shaders to provide a point of excellence greater to our graphics.

- External views that show the parameters of the machine.

- Several cameras to allow the user to change the point of view.

- HUDof light bulbs.

- High quality shadows.

- Friendly graphic interface.

Special conditions

Possibility of working in different time zones: sunrise, morning, afternoon, dusk, night

Atmospheric conditions: wind, rain, fog, snow, etc.

Other conditions

- Realistic response to collisions depending on the level of severity of the same.

- Environmental conditions: smoke, dust, etc.

Main Characteristics

- Allows work in the yard up to 3 heights (1-over-2).

- There are virtual trucks that move autonomously to allow operation with trailers.

- Driving operations through the terminal.

- Allows for carriage moves and lifting operations by the terminal.

- Work in terminal and on the dock.

- Machine response depending on the load.

- Injection of faults by the instructor at runtime.

- Collaborative mode, possibility for several users to interact with each other.

- Existence of an exercise editor to customize your own exercises.

- Auxiliary information window of the status, position and operating commands of the machine.

- Information on the screen for both the user and the instructor.

- Multi language.

- The crane can be parameterized to cover a wide range of operating possibilities.

- Implementation of a system of repetition of exercises for the post-analysis phase.

- Online system for reporting failures or comments by the client.

- Theoretical module.

- Softpanel that allows the control of the crane and its implements through the PC mouse.

For our Straddle Carrier simulator, a complete instructional design divided into blocks has been implemented. Each of these blocks includes a series of exercises that progressively increase their difficulty as the student progresses. The user of our simulator can perform, among others, the following exercises:

- Test type questionnaire.

- Learning and recognition of controls.

- Driving.

- Familiarization with the spreader.

- Work exercises in terminal.

- Container transfer exercises.

- Maneuvering exercises in adverse weather conditions.

Reports and evaluation

- Date.

- Start and end of the session.

- Duration of sessions.

- Registration of the use of controls.

- Completed exercises.

- Speed record.

- Collisions record.

- Registration of dangerous maneuvers.