- Home

- Home

- Mining and construction simulators

- Training Systems

- Port simulators

- Training Systems

- Industrial simulators

- Training Systems

- Gallery

- Training Systems

- Hardware Components

- Hardware

- Simulator Models

- Hardware

- Why Simulators?

- Hardware

- Technical information

- Software

- Our Solutions

- Software

- Instructor Information

- Software

- Collaborative Mode

- Software

- Services

- Services

- Ship-to-Shore Crane Simulator

- Bulldozer Simulator

- Mobile Harbour Crane Simulator

- Mining Truck Simulator

- Wheel Loader Simulator

- Underground LHD Loader Simulator

- Forklift Simulator

- High Capacity Forklift Simulator

- 360 Excavator Simulator

- Mobile Crane Simulator

- Rail Mounted Gantry Crane Simulator

- Tower Crane Simulator

- Rubber-Tyred Gantry Crane Simulator

- Telehandler Simulator

- Grader Simulator

- Reach-Stacker Simulator

- Backhoe Simulator

- Ro-Ro Simulator

- Straddle Carrier Simulator

- WheelDozer Simulator

- Articulated Mining Truck Simulator

- Electric Shovel Simulator

- Empty Container Handler Simulator

- Drilling Jumbo Simulator

- Bridge Crane Simulator

- Farming Tractor Simulator

- Harvester Simulator

- Ship Pedestal Crane Simulator

- Mobile Elevating Work Platform (MEWP) Simulator

- About us

- About us

- Our Learning Methodology

- About us

- Contact

- Contact

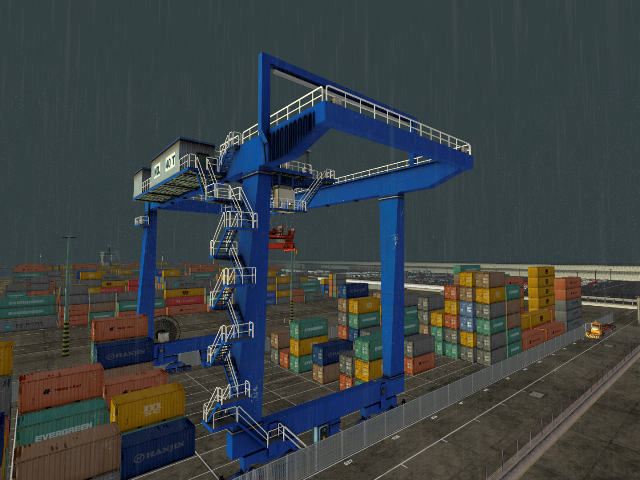

To reduce the loading and unloading times of large container ships, the container terminal area needs to be worked in the best and most efficient way possible. Depending on the degree of automation in modern terminals, this can be done by two types of cranes for containers handling : Rubber Tired Gantry Cranes (RTG) or Rail Mounted Gantry Cranes (RMG).

The function of this type of cranes is to handle the input / output and transferring of containers to blocks or stacks in container storage area (container terminal or railway station).

The RMG cranes are fully electrified. The main power supply and data transmission are handled by highly dynamic and specialized motorized cable reels.

Rail Mounted Gantry Cranes are generally wider and higher than Rubber Tired Gantry Cranes.

Due to the automation of functions and the additional control equipment on board, the requirements for data communication to an RMG crane are much higher. The transmission of energy and data to the RMG crane trolley is carried out by highly resistant electric energy chain systems.

The fully automated Rail Mounted Gantry Cranes are known as automatic stacking cranes (ASC).

Why use the RMG crane simulator developed by LSyM?

By using our simulator the operator will acquire the adequate preparation to be able to carry out operations with this type of crane in a safe way. The simulator developed by the LSyM group allows you to carry out unfeasible risk operations in training with the real crane.

By using our simulator, training costs that would be derived directly from using a real crane will be significantly reduced.

Equipment

- Cabin located on a platform of 2 to 6 degrees of freedom.

- Controls from a real crane.

- Real Operations Console.

- Real environment digital sound effects.

- Instructor console with total control over the simulation.

- Projection system with 2 to 5 high resolution screens.

Visualization system

- Realistic 3D graphics.

- Design and implementation of the indicator light panel based on the real one of the machine (HUD).

- External views displaying machine parameters

- Multiple cameras to allow the user to change the viewpoint

- Implementation of shaders to provide a greater point of excellence to our graphics

- Intuitive friendly user interface

Special conditions

Weather events: wind, rain, fog, snow, etc.

Work in different time zones: sunrise, day, sunset, night

Other conditions

Realistic response to collisions based on their severity.

Environmental conditions: smoke, dust, etc.

Main System Features

- Development of an immersive environment based on "Virtual Reality", techniques analogous to the real environment of a work space of a harbour container terminal.

- The operators will get the control, feel the movements and listen to the sounds produced by the operations performed. In addition, they will see the workspace as if they were in a real RMG crane.

- Real simulation of cable physics.

- Main accelerations and movements are perceived in the cabin.

- Response of the machine directly proportional to the load.

- Auxiliary information window with the status and position of the machinery and the operation commands.

- Multi language interface.

- Fully configurable sensors.

- Injection of failures by the instructor at runtime.

- Online system for reporting bugs or comments by the client.

- Design and implementation of Softpanel that allows the total control of the machine making use of the mouse of the PC.

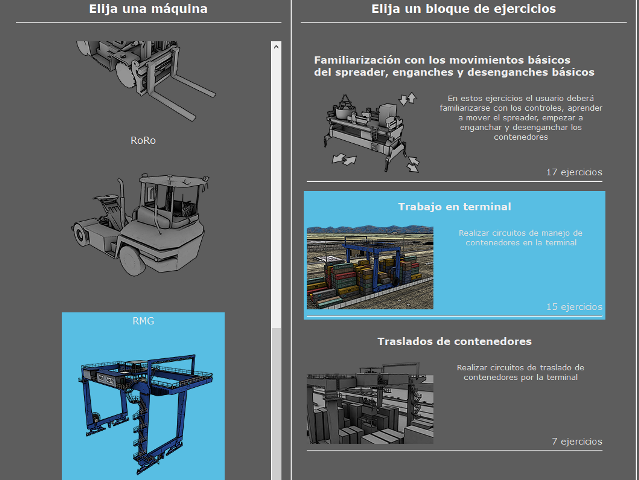

Instructional design

The Rail Mounted Gantry Crane Simulator have been developed by LSyM group has a complete instructional design that guides both the learner and the instructor, using the experience of this, in order to maximize the learning capacity of users.

The main functions available are the following:

- The basic movements of the spreader.

- The basic exercices of container lock-unlock.

- Exercises of terminals work.

- Containers displacement in container terminal area.

- Transfer TEUs.

- Transfer FEUs.

- Exercises with trucks use.

Reports at the instructor's console

- Date.

- Starting and ending time.

- Time length.

- Finished exercises.

- Control handling log.

- Velocity log.

- Collision log.

- Dangerous maneuvers log.