- Home

- Home

- Mining and construction simulators

- Training Systems

- Port simulators

- Training Systems

- Industrial simulators

- Training Systems

- Gallery

- Training Systems

- Hardware Components

- Hardware

- Simulator Models

- Hardware

- Why Simulators?

- Hardware

- Technical information

- Software

- Our Solutions

- Software

- Instructor Information

- Software

- Collaborative Mode

- Software

- Services

- Services

- Ship-to-Shore Crane Simulator

- Bulldozer Simulator

- Mobile Harbour Crane Simulator

- Mining Truck Simulator

- Wheel Loader Simulator

- Underground LHD Loader Simulator

- Forklift Simulator

- High Capacity Forklift Simulator

- 360 Excavator Simulator

- Mobile Crane Simulator

- Rail Mounted Gantry Crane Simulator

- Tower Crane Simulator

- Rubber-Tyred Gantry Crane Simulator

- Telehandler Simulator

- Grader Simulator

- Reach-Stacker Simulator

- Backhoe Simulator

- Ro-Ro Simulator

- Straddle Carrier Simulator

- WheelDozer Simulator

- Articulated Mining Truck Simulator

- Electric Shovel Simulator

- Empty Container Handler Simulator

- Drilling Jumbo Simulator

- Bridge Crane Simulator

- Farming Tractor Simulator

- Harvester Simulator

- Ship Pedestal Crane Simulator

- Mobile Elevating Work Platform (MEWP) Simulator

- About us

- About us

- Our Learning Methodology

- About us

- Contact

- Contact

Underground LHD (Load-Haul-Dump) Loader is a machine of compact design in height as well as width to adapt to the excavation track, it is highly maneuverable and exceptionally productive.

Using the LHD loaders the same operator loads the bucket, transports the load along the tunnel and unloads it at the point of discharge, then repeats the cycle.

Work in underground mines requires the use of equipment with specialized designs for these jobs, which is why LHD loaders are suitable for these tasks.

Occupational hazards arising from its use

By means of the Underground LHD (Load-Haul-Dump) Loader Simulator developed by the group LSyM, the operators will obtain the skill and knowledge necessary to avoid or to know to act in situations of risk such as:

- Loss of vehicle control on sloping roads and ramps

- Blows or entrapments of operators or other vehicles with the equipment

- Inclination and tilting the vehicle

- Congestion within the work area

- Collisions with airborne obstacles, for example, ceilings, pipes or low suspenders

Equipment

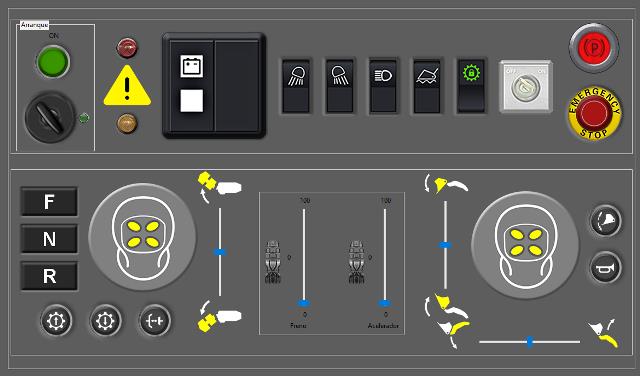

- Cabin located on platform with 2 to 6 degrees of freedom.

- Real operation console.

- Driving pedals.

- Instructor's console with full control over the simulation.

- Real environment digital sound effects.

- Projection system with 2 to 4 high resolution screens.

Visualization system

- High quality images, generated in real time.

- Real 3D graphics.

- External views displaying machine parameters.

- Multiple cameras that can be selected by the user to change the viewpoint.

- Stereoscopic mode.

Special conditions

- Environmental conditions: smoke, dust, etc.

- Work with artificial light.

- Realistic response to collisions based on their severity.

- Faults in the machine.

Main functions

- Theoretical module.

- Real machine start and stop sequence.

- Driving and operating in a highly realistic 3D underground mining environment.

- Unload material to trucks.

- Storage of material.

- Automatic and manual gearbox simulation.

- Response of the machine depending on the load.

- Avatars.

- Screen information for both the user and the instructor.

- Information window with the status and position of the machinery and the operation commands.

- Design and implementation Softpanel that allows the total control of the machine making use of the mouse of the PC.

Instructional design

- Theoretical module.

- Exercise Manual.

- Database to store the information of the evolution of the operators.

- Programmed learning monitoring system for each student.

- Summaries, reports, etc.

- Guided practices on the screen and through acoustic messages.

- Record of non-permitted operations and dangerous operations.

Reports at the instructor's console

- Date.

- Starting and ending time.

- Time length.

- Finished exercises.

- Control handling log.

- Velocity log.

- Collision log.

- Dangerous maneuvers log.